Product/Services

Rubber Lining

CORROSION PROTECTION – We are in a position to assist in combating this problem by providing appropriate rubber lining protection.

PT. Inderizqo Bintang Sejahtera is the foremost linier in Indonesia today. Reaction vessels and rubberized in natural and synthetic rubber compounds in hardness from 30 to 90 shore ‘A’ for soft rubber compounds and 60 to 80 shore ‘D’ for hard rubber compounds. In case of intense changes in temperatures, shock and impact are expected, we can provide specially developed Triflex and Duplex rubber lining for such requirements. In case of extremely large vessels which cannot be transported, we can carry out rubber lining at users work site.

RUBBER LINING MATERIAL TYPE

- Soft Natural Rubber

- Hard Rubber

- Butyl Rubber

- Choloprene Rubber

- Choloprene Rubber

- Hypalon Rubber

- Duplex Rubber

- Triplex

Fabrication

Our Fabrication Project

- Storage Tank

- WWTP rectangular Tank

- Air Cooler Heat Exchanger

- Stainless 304

- Batching Plan

- Chemical Dosing Pump System

Polyurethane

Polyurethane Is a polymeric material that contains various groups of Urethane(-NH-CO-O-) formed from the reaction of polyols (alcohols with more than two hydroxyl groups Reactive per molecule) with diisocyanates or polymeric isocyanates with availability

Appropriate catalysts and additives.

Polyurethane Elastomer is a solid polyurethane that can be used as a coating or adhesive material for an item to make it look good and durable. It also has very elastic, flexible, abrasion-resistant, impact-resistant and weather-resistant properties.

Some of the Advantages of Polyurethane:

- Violence is very diverse, from Shore A to Shore D

- Extremely wear-resistant

- Very very resistant to blows

- Very very resistant to friction

- Suitable for Heavy duty Industry

- Excellent suppleness and resistance to fatigue

- Remain flexible against low temperatures

- Good insulation ability

- Resistance to deterioration caused by the atmosphere, oxygen and ozone. 10. Resistant to oil, grease and some chemicals.

Rubber & Ceramic Lagging

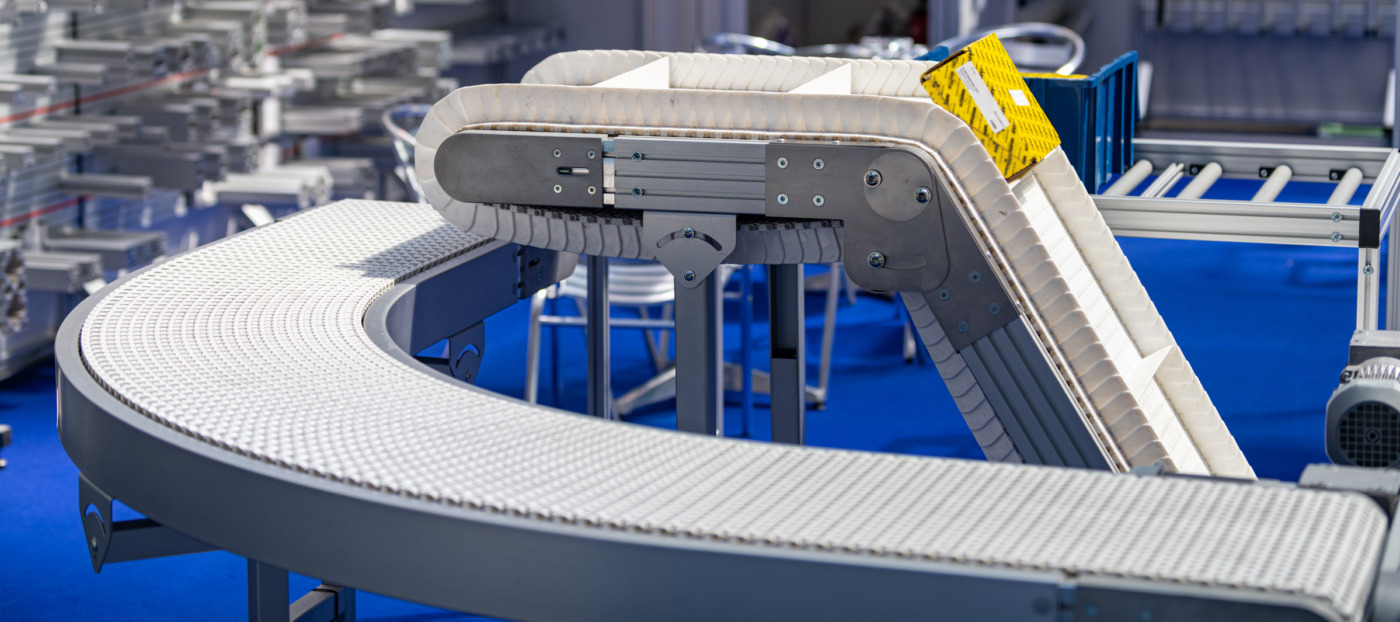

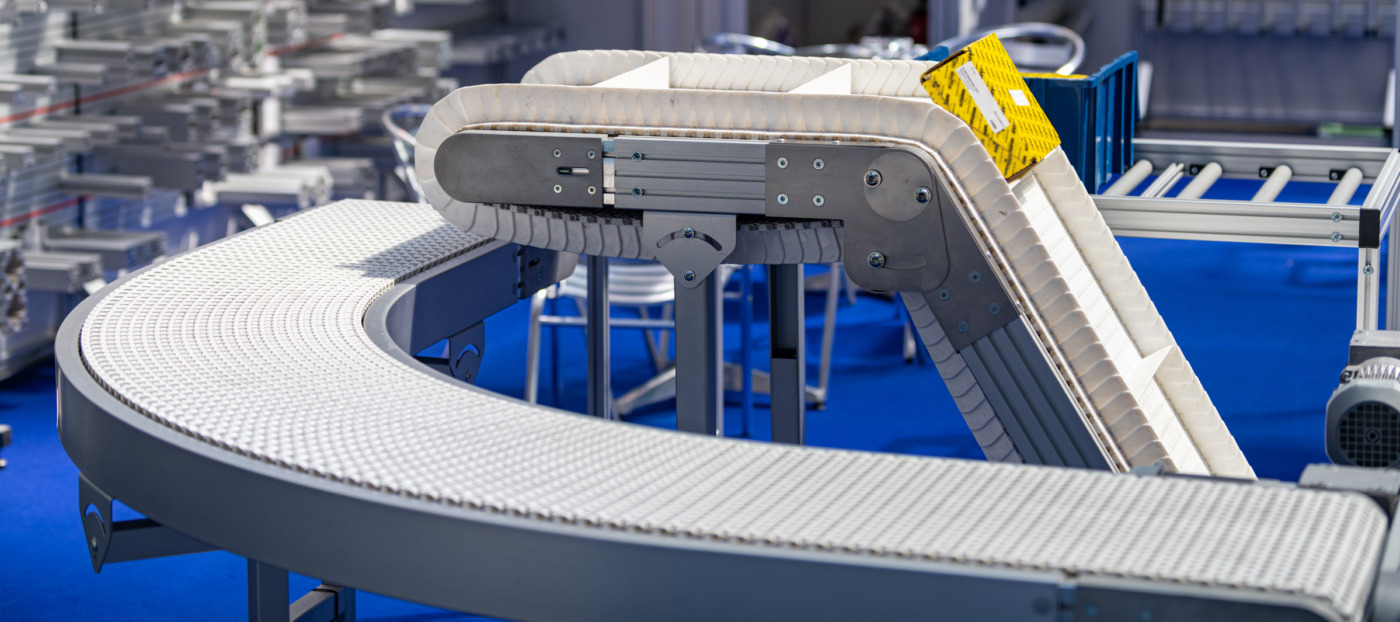

Conveyor Belt & System

There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport industrial and agricultural materials, such as grain, coal, ores, etc. generally in outdoor locations. Generally companies providing general material handling type belt conveyors do not provide the conveyors for bulk material handling. In addition there are a number of commercial applications of belt conveyors such as those in grocery stores.

The belt consists of one or more layers of material. They can be made out of rubber. Many belts in general material handling have two layers. An under layer of material to provide linear strength and shape called a carcass and an over layer called the cover. The carcass is often a cotton or plastic web or mesh. The cover is often various rubber or plastic compounds specified by use of the belt. Covers can be made from more exotic materials for unusual applications such as silicone for heat or gum rubber when traction is essential. Material flowing over the belt may be weighed in transit using a beltweigher. Belts with regularly spaced partitions, known as elevator belts, are used for transporting loose materials up steep inclines. Belt Conveyors are used in self-unloading bulk freighters and in live bottom trucks.

Conveyor technology is also used in conveyor transport such as moving sidewalks or escalators, as well as on many manufacturing assembly lines. Stores often have conveyor belts at the check-out counter to move shopping items. Ski areas also use conveyor belts to transport skiers up the hill. A wide variety of related conveying machines are available, different as regards principle of operation, means and direction of conveyance, including screw conveyors, vibrating conveyors, pneumatic conveyors, the moving floor system, which uses reciprocating slats to move cargo, and roller conveyor system, which uses a series of powered rollers to convey boxes or pallets.

Rubber Molding & Sealing

Moulded and Special Industrial Rubber products PT. IBS is continuously developing rubber accesories to meet the sophisticated demand of modern machines. We cater to textile, Filament, Chemical, Oil Drilling, Plastic, Shipping, Leather, Pharmaceuticals, Electrical and many other industries. Rubber to Metal bonding is our speciality can assure of required Bond strength. Rubber sleeves, Bushes, Friction Whels, Trolley Wheels, Gaskets, Pickers, Diaphragms, Trays, Engine mountings, Foundations Blocks, Club-couplings, Flexible couplings, Anti-vibration mountings and various ous other such parts are developed at PT.INDERIZQO BINTANG SEJAHTERA

Fiber Reinforced Polymer

An important feature of fibre reinforced polymer composites (FRP) is their extremely high corrosion resistance. This makes them suitable for use in structures subjected to severe environmental exposure. Applications for FRP bars as internal reinforcement in concrete structural members include parking garages, multi-storey buildings and industrial structures. In many of these applications provision of appropriate fire resistance is one of the major design requirements.

Similar to other materials, the properties of Fiber Reinforced Polymer composite materials deteriorate when exposed to fire. One of the major concerns with FRP reinforcing bars is the loss of strength and stiffness at elevated temperatures. There is very little information in literature on the variation of strength and stiffness of FRP with temperature [1,4,5].

To develop such information on strength and stiffness degradation with temperatures for FRP at elevated temperatures a joint research program between University of Manchester, U.K., and NRC was initiated. As part of this project, experimental studies on the tensile mechanical properties of steel and FRP bars at elevated temperatures were undertaken.

Results from these experimental studies are presented in this paper to illustrate the comparative variations of tensile strength and stiffness of different types of FRP bars with traditional steel rebars. The objective of these tests is to develop material property data on the variation of strength and stiffness of FRP reinforcement bars at elevated temperatures that can be used in computer models for evaluating fire resistance of concrete structural members reinforced with FRP rebars.

FRP Product